So, are you sick and tired of having the bolts on your car or bicycle too loose or at far too tight? When everything is not exactly so, it can be super annoying. That’s where 토크 렌치 렌치 come into play, helping you achieve the perfect tightness every time. These unique bits attach to the end of a device known as a torque wrench. This tool allows you to apply the correct amount of torque to the bolt. With the appropriate bit, a torque wrench ensures a bolt that is neither overtightened nor loose. Tightening bolts too much can break bolts or damage them. If they are too loose they can fall off, which leads to accidents or problems.

For project work, accuracy is extremely important. You may not want to underdo it or overdo it on a bolt, as that can have negative effects. Torque wrench bits give you an example of torque that is straight at your fingertips. It means you can really minimize the amount of force you hit with. Choose the correct bit and set the wrench to the correct torque, and you get the exact amount of force needed for the job. This is particularly useful when you need to ensure that everything is proper and safe.

If you're familiar with torque wrenches, you probably know how expensive it is to purchase multiple wrenches designed for different jobs. But then that was part of their job, with interchangeable bits you can customize your torque wrench to make work for your needs. That means, rather than buying the myriad wrenches you need, just change the bit you’re using and get to work. Not only does this save you money, it also saves space in your toolbox. No need to haul around a variety of wrenches, making it easier to stay organized and compact.

As with all tools, torque wrenches require some TLC to maintain their best performance. Investing in quality bits makes a significant difference in the longevity of your wrench. Use cheaper bits, and they quickly wear out. This can give faulty torque readings, which can screw up your project and damage things. Buy quality rather than quantity always. Hangzhou Naizhun: High-Quality Torque Wrench Bits. You can be sure that your tools will be in great functionality for years down the line this way.

Different jobs need different torque settings. Different bolts require different horizontal forces to sinch down properly; you cannot use the same torque setting to small bicycle bolt as of a larger car lug nut. It is extremely essential to select a suitable torque wrench bit for the task as it means doing the job the right way (often the only way). Using the proper bit also ensures that you can get the bolt to be just right, preventing issues down the line. Hangzhou Naizhun 토크 렌치 are available in many different styles, so no matter what they're using these tools for, they can find what they need.

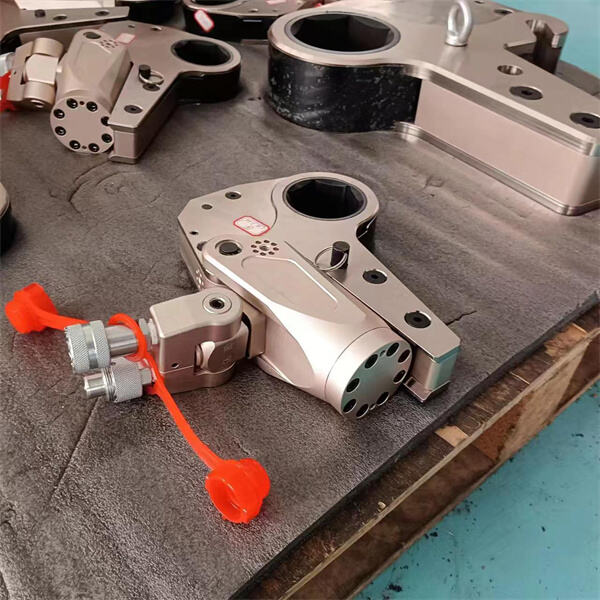

torque wrench bits Naizhun uses high-quality materials in its manufacturing process and adheres to strict processes. Hydraulic tools are built to endure high-intensity, repeated use, without easily being damaged. We offer customized services to many hydraulic tool manufacturers that allow manufacturers to develop and build equipment that is designed to perform specific functions according to the requirements of customers, thus providing personalized solutions to them.

As a manufacturer that has a long history Hangzhou Naizhun invests more resources in technological research and development to torque wrench bits its advantage on the market It is also a firm believer in the quality of its products and has earned international quality certification Our current products comprise of hydraulic torque wrenches high-pressure hydraulic pumps and hydraulic manual pumps bolt stretchers as well as a variety of hydraulic accessories etc 90% of our processes are processed and manufactured at our facility which means we can control our manufacturing quality

torque wrench bits allow manufacturers to market their products in various areas of the world with support and service to their customers across the globe Top-quality customer service comprises the pre-sales consultation support after sales and technical training so that customers can use and maintain hydraulic tools correctly and extend product life The reputation of the brand and feedback from users over time helps improve customer trust and boost the number of sales for products

During the process of designing packaging ensure you maintain an open and honest conversation with your clients Inviting them to provide any packaging requirements that they might have and then ensure the torque wrench bits packaging is in line with their expectations When tools require extra shock protection foam linings can be effective in cushioning any external impact and safeguard tools from harm Internal compartments can be tailored to the exact shape and size of the tool if it is made up of components or has special shapes that need special protection